UL 3321

UL 3321

Application

Internal wiring of electrical, electronic and medical equipment and in appliances with the working high temperature

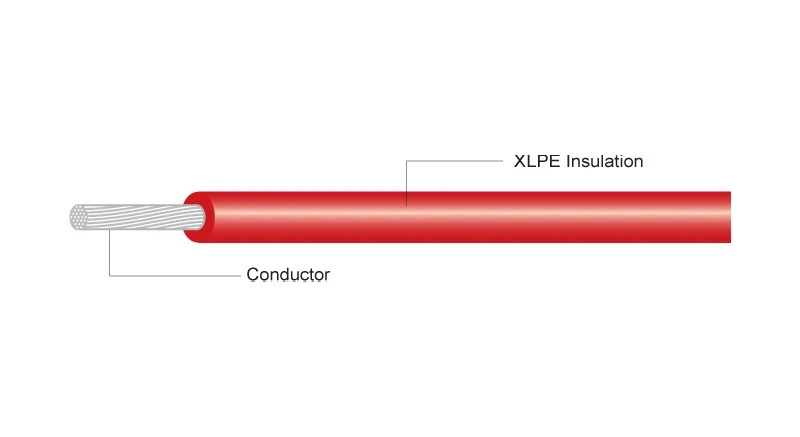

Product Description

Standard UL, CUL AWM I A/B

Conductor Solid , Strand and OS-1 either tinned or bare copper

Rating UL 3320 90° C 600V

UL 3321 150° C 600Vac/ 750Vdc

Flammability UL VW-1, CUL FT1

Insulation Heat resistant XLPE which is cross-linked by electron beam machine and stable

thermally

Usage Uniform thickness of wire to ensure easy stripping and cutting

Resistant to acids, oils, alkalines, moisyure and fungus which are excellent compared with normal PVC wire